Centrifugal Sifter GS

Centrifugal sieving solutions for bulk solids and powder

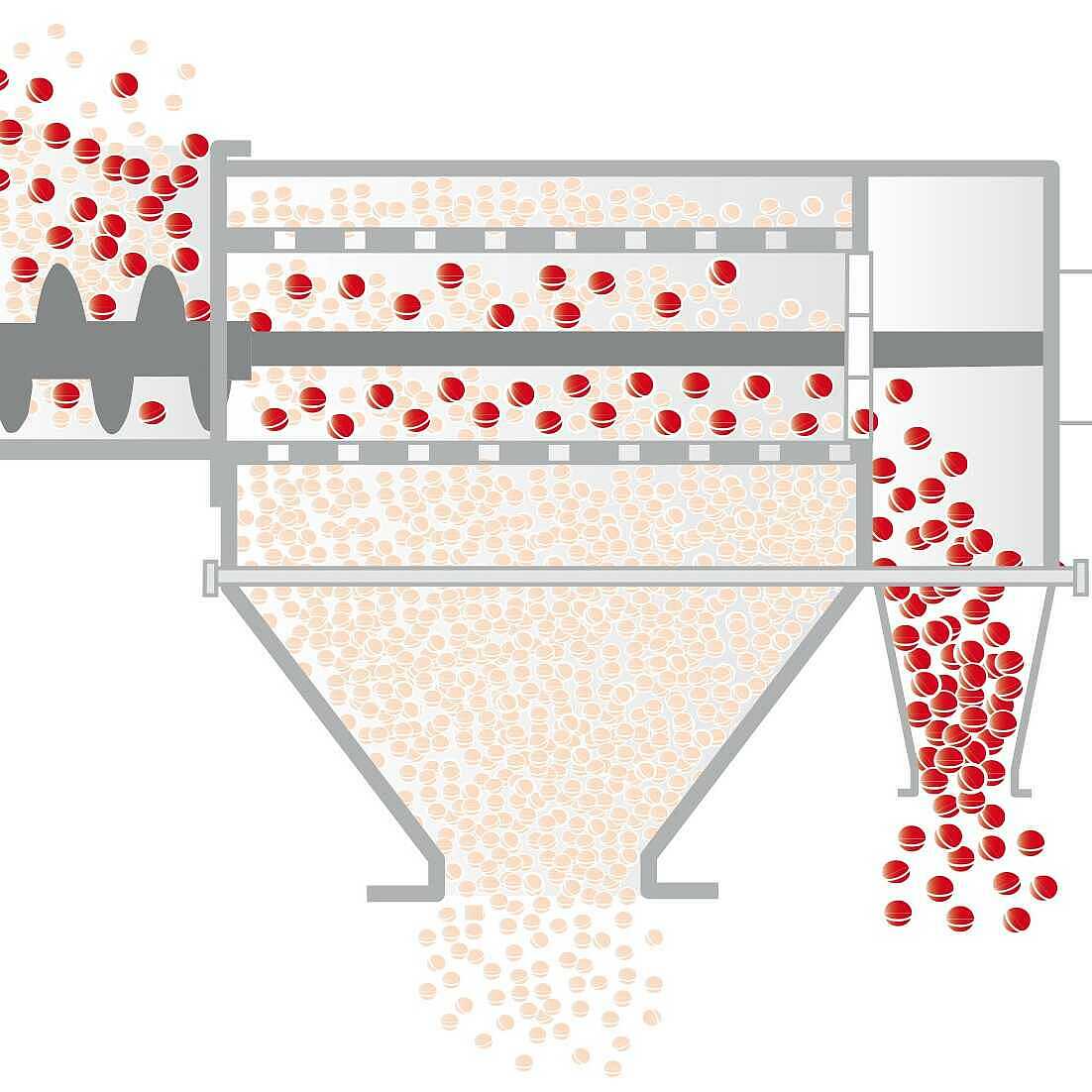

The Gericke centrifugal sifter is a rotary sieving machine (also known as a redresser) designed to separate particles of different sizes into two product streams and to remove tramp and oversize materials. Gericke rotary sifters are specifically designed to meet the increasing demands of modern applications and processes. The machine range, sizes, features and configurations can be optimised for a wide variety of sifting applications.

Centrifugal Sifter GERICKE GS

The Gericke centrifugal sifter is a rotary sieving machine designed to separate particles of different sizes into two product streams and to remove tramp and oversize materials. Gericke rotary sifters are specifically designed to meet the increasing demands of modern applications and processes. The machine range, sizes, features and configurations can be optimised for a wide variety of sifting applications.

Gericke Sifters are an evolution of a design classic

Whilst the principle of centrifugal sifting has remained constant, the demands of modern processes are ever increasing.

Remaining one-step ahead of these demands requires a centrifugal sifter that provides time-proven application technology, yet allows for rapid inspection, cleaning, change-over, repeatability, access and maintenance. All of which combine to minimise down-time, increase yield and maximise productivity.

The benefits of Gericke Sifters

- The centrifugal sifter can increase throughput, improve efficiency and maximise profitability.

- A rotary sieve machine has a smaller footprint per tonnage throughput and provides low power consumption, low noise levels and increased efficiency in comparison to a flat deck sieve.

- Gericke manufactures centrifugal sifter screens for a wide variety of bulk sieving applications, our basket and sifter screen assemblies feature 360 degree basket and screen inspection, positive basket location and engagement.

Range of Gericke Sifters

Gericke centrifugal sifter machines are available in a range of sizes, the machine size is defined by the dimensions of the sieve surface; our GS 722 rotary sieve has a sieve area measuring Ø 7” x 22” long, rising to our largest machine GS 1542 with a sieve area of Ø 15” x 42” long

All variants are available in carbon steel, 304 stainless, or 316 stainless steel with a number of surface finish options to suit your particular application.

Each sifter can be individually configured using a range of features and options designed to tailor the machine to your requirements to suit almost any sifting duty and can be specified for ATEX and non-ATEX duties.

Applications

To guarantee product quality within processing materials, Gericke centrifugal sifters provide three main operational processes:

- Particle separation: To separate products with a varying particle size into two fractions, typically within the range of 40 µm to 5 mm.

- Safety sifting: Removal of foreign parts and tramp material prior to product entering a production process, or to secure product quality before filling.

- Conditioning: To separate foreign bodies and condition the product bulk density prior to production or immediately before packing.

High level performance

Gericke sifters have been designed and developed for the optimization of these sifting tasks. The basic principles of centrifugal sifting, provides high level performance and optimum separation with a minimal footprint.

Sifting capacities from 2 kg/h guaranteeing product quality of high value small batch operations, up to 120 t/h minimising the time-frame for filling of road tankers, a preferred method utilized throughout the milling industry and the production and processing of sugar and starch.

For more information:

Inquiry

Downloads

Expertise. Value. Trust.