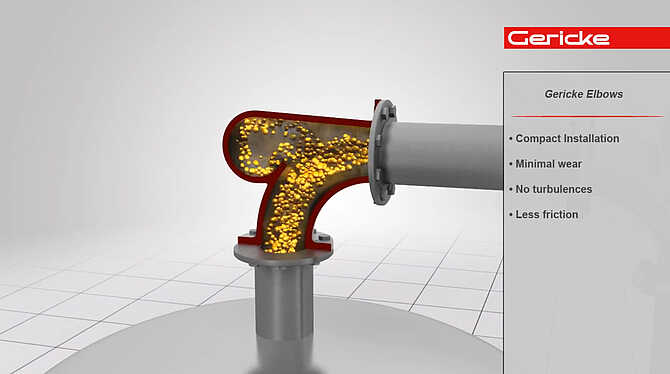

Elbows GB

Increase the lifetime of your bends!

Increase the lifetime of bends for pneumatic conveying of abrasive materials with the Gericke Bend GB. Due to the special vortex chamber, the wear rate of bends for pneumatic conveying is drastically reduced. The lifetime cycle will be extended and your maintenance and downtime costs will be reduced.

Your Benefits

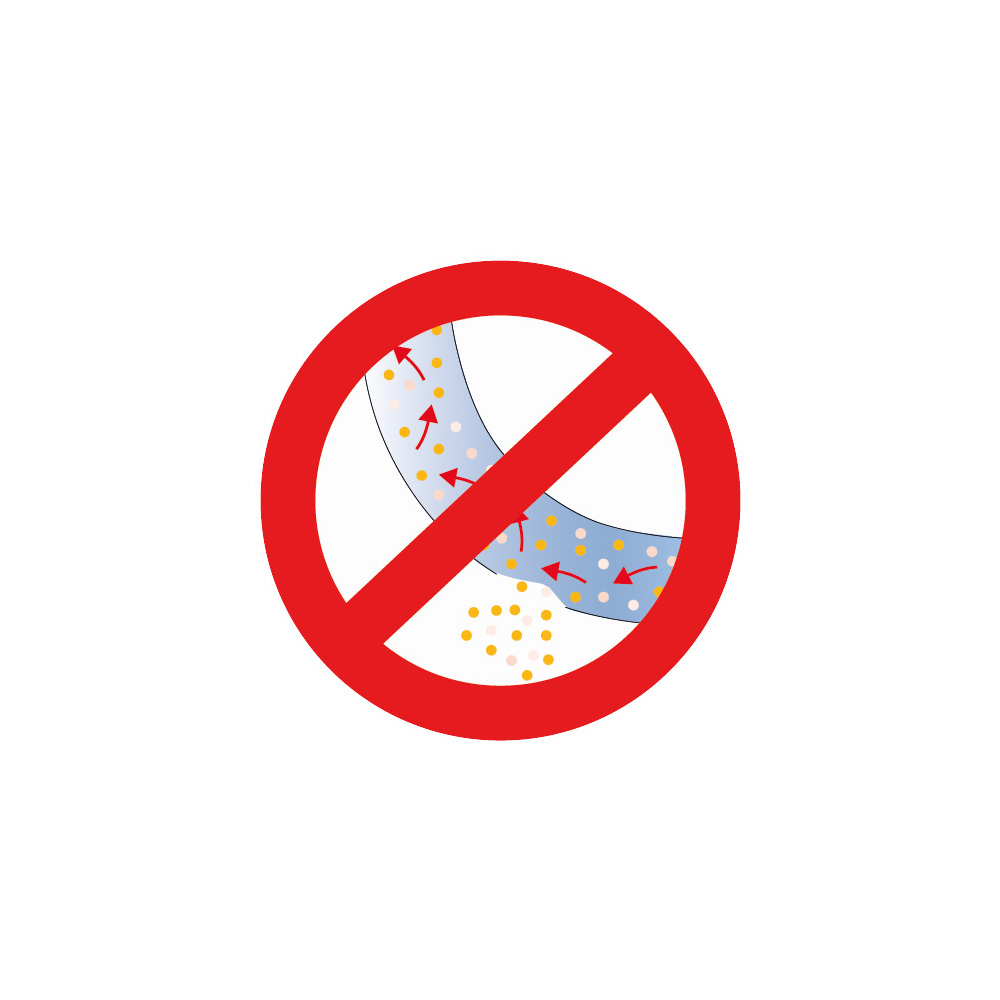

- Reduces wear

- Reduces maintenance, downtime and operating costs

- Reduces angel hair in conveying of plastic granulates

- Lower space requirements as it is a space saving way to divert the conveying pipe direction by 90 degrees

Specifications

- The Gericke Bends are available in sizes from DN50 up to DN200.

- Standard material is modular cast Iron (GGG-70) with a very high hardness.

- Optional stainless steel cast 1.4408 can be delivered.

- Flange dimensions DIN EN1092-1 PN16. ANSI on request.

Elbow installed

Standard pipe

Applications

- Conveying of abrasive materials

- Dense phase (except PulseFlow) or lean phase

- Positive or negative pressure (vacuum)

- For both powders and pellets.

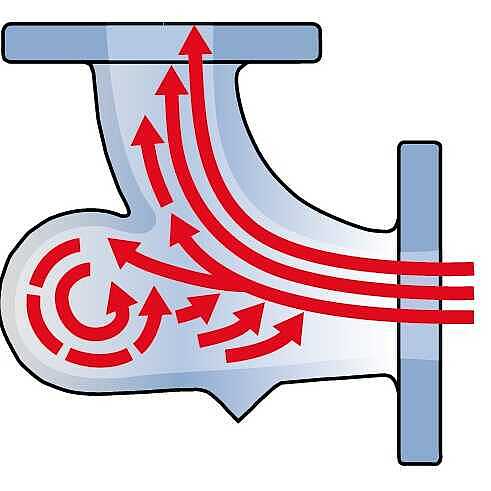

Principle of operation

The conveyed product changes direction due to the deflection in the special vortex chamber and not due to the impact on the bend wall. Therefore, the Gericke Bend significantly reduces wear and failure for pneumatic conveying of abrasive bulk materials.

Function principle

For more information:

InquiryExpertise. Value. Trust.